INFRASTRUCTURE

MANUFACTURING ASSETS

3 State-of-the-art manufacturing plants Total Plant Area : 1.7 mn. sq. ft. Total Land Area : 2 mn. sq. ft.

MADE-TO-MEASURE

A fully equipped made-to-measure plant for curtains and blinds and made ups division capable of servicing both domestic and export markets.

INVENTORY MANAGEMENT

3 strategically located warehouses including a fully robotized central warehouse serving 1000+ retailers across the country.

WORKFORCE

3,000+ Employees

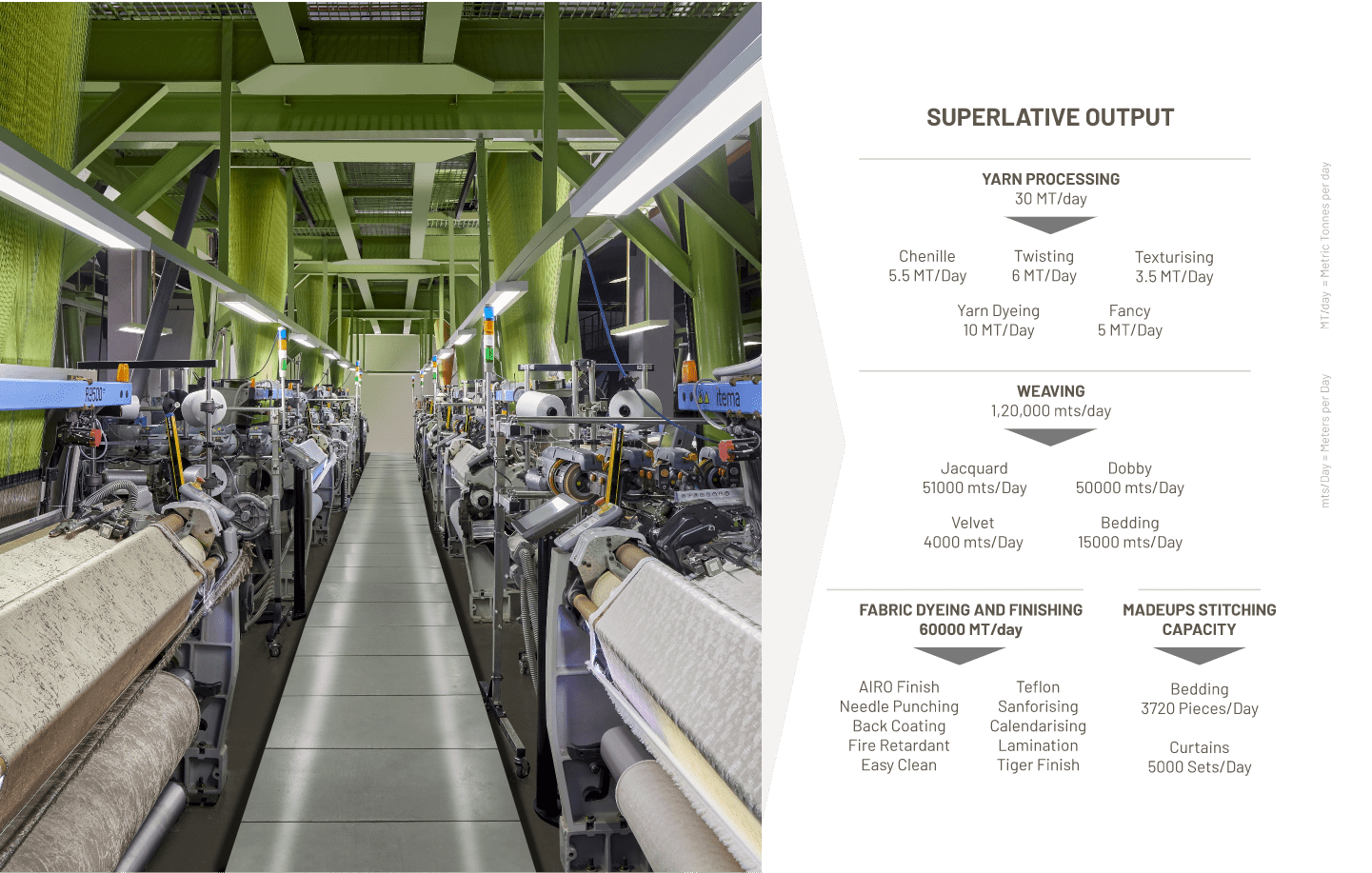

CAPACITY

Daily output: 120,000 metres

DESIGN LIBRARY

20,000+ copyrighted designs

MANUFACTURING

It all begins at our 3 state-of-the-art plants in Tarapur, India. Each year, 44 million metres of fabric is woven here, destined to beautify homes around the world.

Featuring cutting-edge equipment with an average age of just 4 years, our Tarapur facilities exhibit just how much we love embracing technology and the spirit of reinvention. We are proud to have delivered several prominent firsts in Indian textile manufacturing such as creating water-repellent and flame-retardant fabrics, as well as the country’s first robotic warehouse.

AUTOMATION

With the continuing need to drive greater throughput, reduce costs and improve FTR, our manufacturing is augmented with many Industry 4.0 solutions to increase their efficiency.

FIVE FULLY AUTOMATED ROBOTIC WAREHOUSES IN INDIA

First mover in automatic storage and retrieval system (ASRS) in Indian textile industry for Yarn, Grey Fabric, Finished Fabric, cut-length business, and all samples. Industry leading European partner for automation - AutoMHA (Italy)

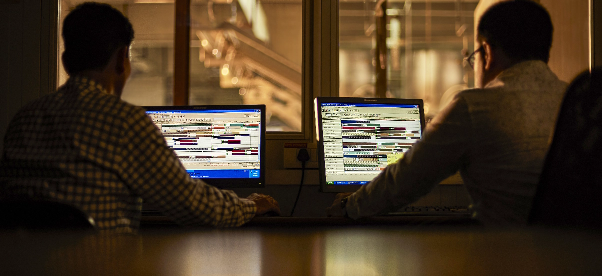

PRODUCTION PERFORMANCE AND QUALITY MANAGEMENT SOFTWARE

Descriptive and graphical display of every production batch, in width and depth through the OrgaTEX® Process Analyzer. The visualization is configurable to show the essential items of the production process down to every sensor detail.

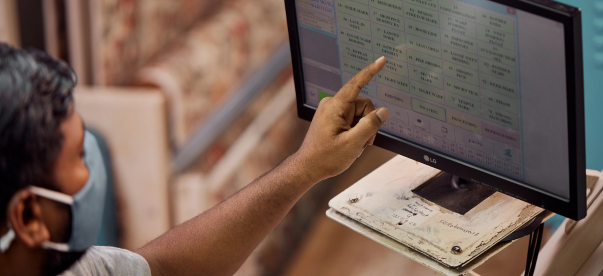

REAL TIME INSPECTION

Fabric 4-Point defect logging using Real-Time inspection software for auto-cutting and packing of fabrics delivering a better quality control and lesser fabric wastage.

NABL ACCREDITED FABRIC TESTING

Capable of Comprehensive chemical and mechanical tests applicable across US, the UK, Europe and other markets.

Licensed CAD-CAM SYSTEM FROM LEADING EUROPEAN DESIGN SOFTWARE HOUSES

100% automation and data security from design creation to manufacturing stage.

DYE-STUFF DISPENSING

Automatic dosing system for dyeing production with consistent quality and large scale fabric dyeing.

INDUSTRY 4.0

Keeping pace with technology in a challenging market

DIGITAL MANUFACTURING

- - Harmonised data analytics

- - Unified manufacturing modelling

- - Integrated manufacturing operations management

MANUFACTURING EXECUTION SYSTEM (MES)

- - Centralised operations

- - Automated data collection

- - Defect tracking and resolution

PRODUCTION PLANNING & SCHEDULING

- - Comprehensive planning features

- - Integrated scheduling

INDUSTRIAL INTERNET OF THINGS (IIOT):

- - Manufacturing analytics platform

- - Energy monitoring and analysis

- - Overall equipment effectiveness (OEE)